Solar Panel Cleaning in France – Structure and Daily Routines in the Field

In France, solar panel cleaning supports the maintenance of photovoltaic systems across various regions. The work includes outdoor cleaning, debris removal, and adherence to safety guidelines. This overview explains how the activity is structured and how it contributes to the country’s expanding renewable energy framework.

Understanding Solar Panel Cleaning France Operations

The solar energy landscape in France has experienced substantial growth over recent years, creating specialized maintenance requirements for thousands of installations. Solar panel cleaning France operations involve systematic approaches to preserving the efficiency of photovoltaic systems through regular removal of dust, pollen, bird droppings, and environmental debris. Unlike standard cleaning tasks, this work requires understanding of electrical systems, safety protocols around high-voltage equipment, and techniques that prevent damage to delicate solar cell surfaces. The field encompasses various technical considerations related to equipment handling and safety measures specific to rooftop and ground-mounted solar arrays.

Maintenance Routines in Photovoltaic System Care

Maintenance routines for photovoltaic systems follow structured schedules determined by location, environmental conditions, and installation specifications. Typical cleaning cycles range from quarterly to semi-annual intervals, though installations near agricultural areas, coastal regions, or industrial zones may require more frequent attention. Standard procedures involve site assessment, checking weather conditions, and preparing equipment including water-fed poles, soft brushes, deionized water systems, and safety gear. The actual cleaning process involves methodical panel-by-panel work, visual inspections for damage or wear, and documentation of conditions observed.

Structured Cleaning Work Protocols

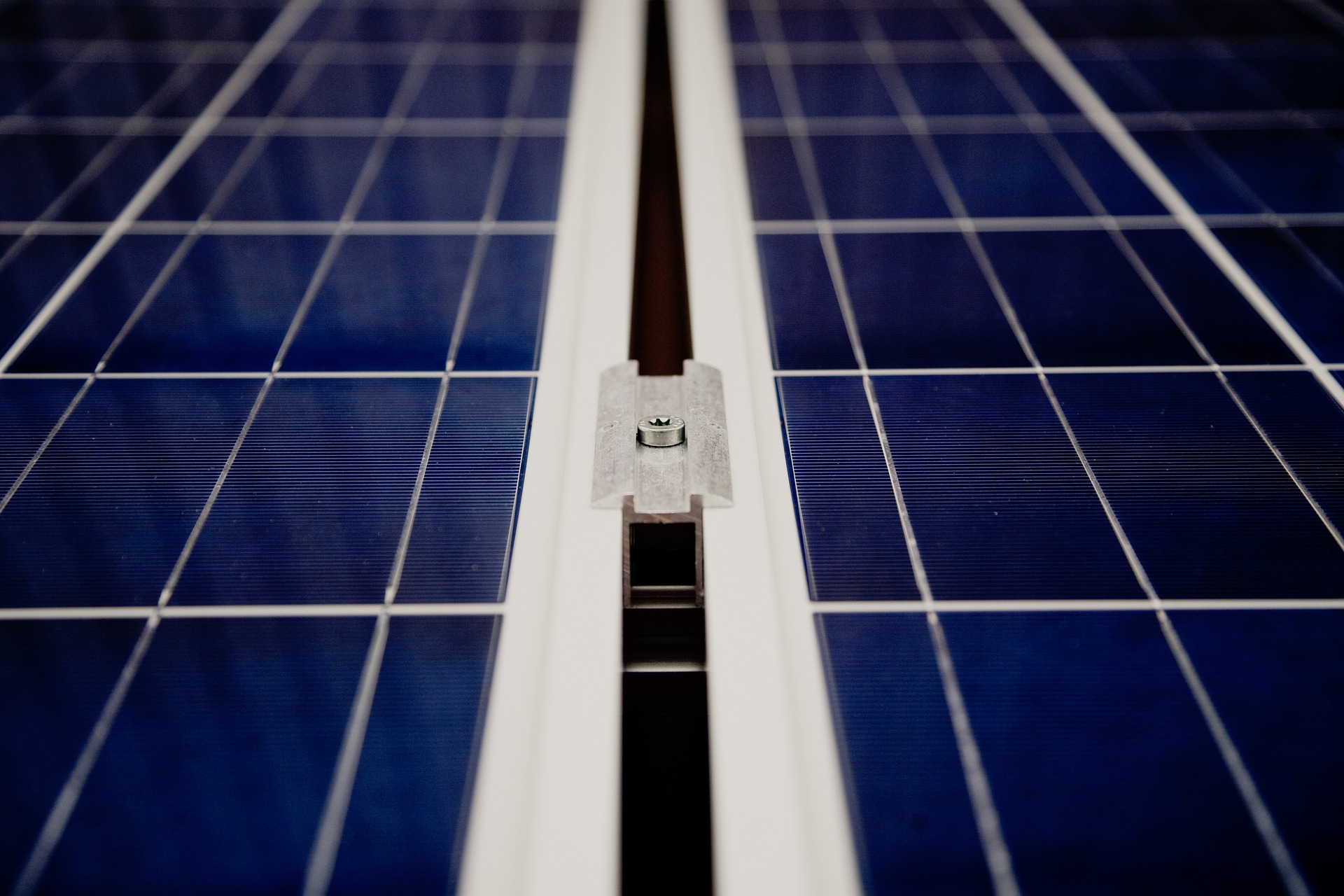

Structured cleaning work in the solar maintenance field follows established protocols designed to maximize efficiency while protecting both workers and equipment. Standard procedures include pre-cleaning inspections to identify potential hazards, systematic cleaning patterns that ensure complete coverage, and post-cleaning verification of panel functionality. Ground-level installations may allow for relatively straightforward access, while rooftop systems require additional safety equipment including harnesses, anchor points, and fall protection systems. Documentation forms an essential component of structured work, with maintenance logs recording dates, conditions, observations, and any issues requiring technical attention.

Renewable Energy Sector Context

The renewable energy sector in France encompasses diverse technical and operational activities, from engineering and installation to ongoing maintenance and operations. Within this broader field, cleaning and maintenance activities represent specialized functions that require physical capability, attention to detail, and willingness to work outdoors in varying weather conditions. Geographic distribution of solar installations varies across France, with higher concentrations in southern regions where solar adoption rates are elevated. The sector continues evolving as renewable energy infrastructure expands throughout the country.

Daily Work Structure and Physical Requirements

Typical maintenance activities in solar panel care begin early to take advantage of cooler morning temperatures and optimal lighting conditions. Physical requirements include ability to work at heights, carry equipment weighing up to 15-20 kilograms, maintain balance on sloped surfaces, and perform repetitive motions throughout extended periods. The work involves significant time outdoors, exposed to sun, wind, and varying temperatures, making appropriate clothing and sun protection essential. Activities include climbing ladders, walking on rooftops, and operating specialized cleaning equipment. Attention to safety remains paramount, with regular breaks scheduled to prevent fatigue-related accidents.

Training and Technical Knowledge

Solar panel cleaning requires basic knowledge of safety procedures, equipment operation, and cleaning techniques specific to photovoltaic systems. Understanding of electrical systems, proper handling of delicate solar cell surfaces, and awareness of potential hazards form essential components of the technical knowledge base. Certification programs exist for renewable energy technicians, though specific credentials for cleaning specialists vary by context and application. Advanced knowledge areas may include electrical awareness, specialized techniques for different panel types and mounting systems, and facility management principles related to renewable energy installations.

Conclusion

Solar panel cleaning in France represents a specialized technical field within the expanding renewable energy sector, characterized by structured work routines, specific safety requirements, and physical demands distinct from conventional cleaning activities. As photovoltaic installations continue proliferating across French territory, maintenance services remain essential to preserving system efficiency and longevity. Understanding the technical realities, physical requirements, and operational structures of this work provides perspective on the specialized nature of renewable energy maintenance activities.