Mechanic Training Basics and Workshop-Oriented Learning

If you live in Stuttgart and speak English, you can learn how mechanic training is typically arranged. The field combines introductory technical theory with routine workshop exercises, allowing learners to understand how mechanical systems are handled in a structured environment.

Mechanic training succeeds when theory directly supports practice. Workshop-oriented learning emphasizes repeatable routines, safety-first habits, and verifiable results. In Germany, many programs combine classroom instruction with supervised shop time, allowing learners to connect mechanical concepts to tools, materials, and real equipment. The outcome is practical competence built on a shared language of measurements, tolerances, and documented procedures.

Mechanical system basics

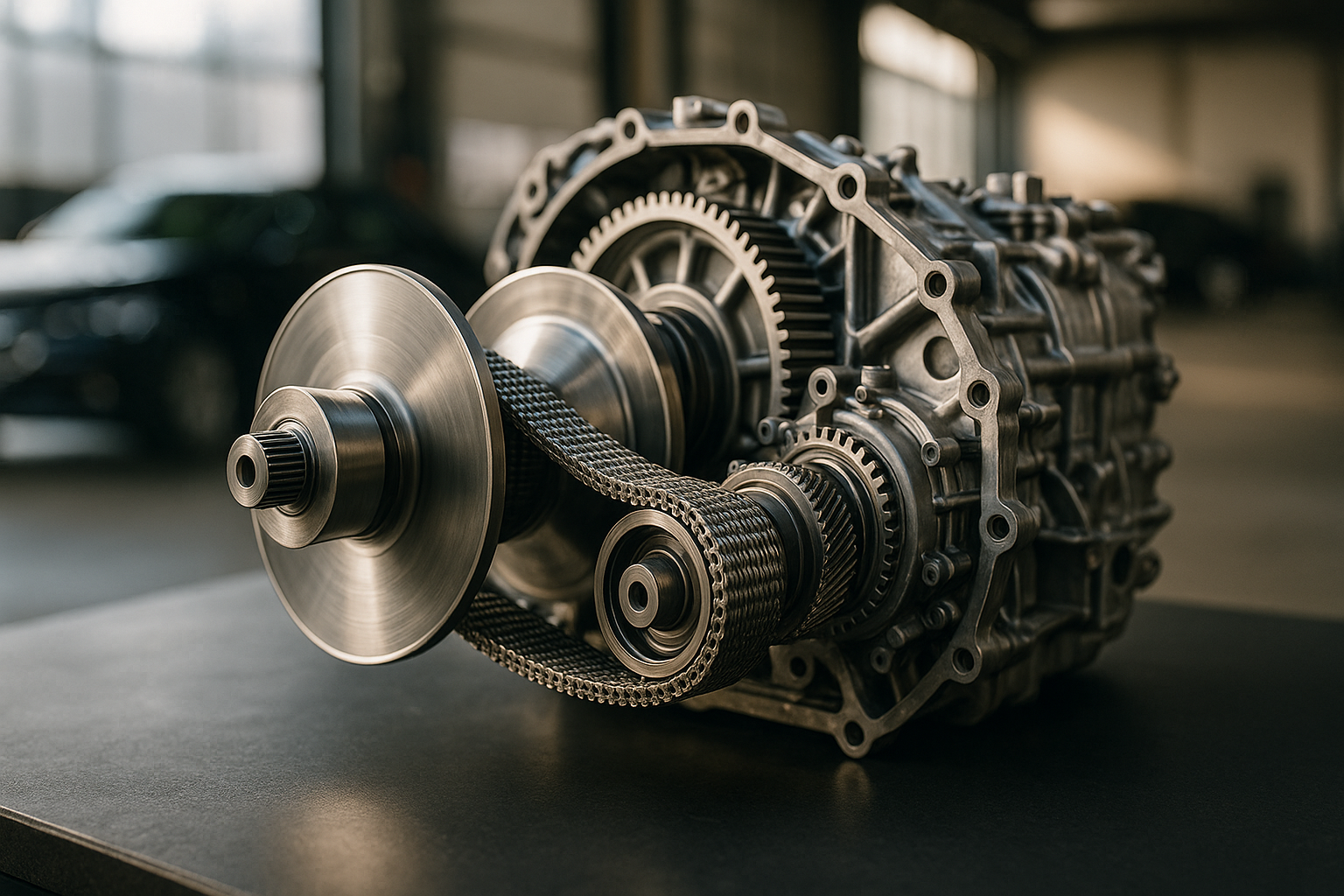

Mechanical systems convert and control energy through components such as shafts, bearings, gears, belts, and chains. A solid grasp of forces, torque, motion, and friction helps learners understand how parts interact and why failures occur. Training typically covers materials (steel, aluminum, polymers), surface finishes, and heat treatment because these factors influence wear, strength, and service life. Learners practice reading technical drawings with dimensions, symbols, and tolerances to ensure precise fits. Measurement tools—calipers, micrometers, dial gauges, and torque wrenches—anchor accuracy. By mastering these mechanical system basics, trainees can diagnose misalignment, improper torque, or incorrect clearances before problems escalate in the workshop.

Routine workshop exercises

Progress depends on repetition with feedback. Routine workshop exercises include measuring and marking out, filing and deburring, drilling and tapping, and assembling fasteners with correct torque. Learners practice shaft–bearing fits, belt tensioning, chain alignment, and basic lubrication tasks. Cleaning and inspection routines foster reliability: checking seals, examining wear patterns, and gauging runout on rotating parts. Simple machining tasks (such as facing and drilling on a bench lathe under supervision) help learners understand feeds, speeds, and tool wear. Daily housekeeping and tool control reduce risks and downtime. Over time, these routines become second nature, supporting safe, consistent work on actual assemblies found in service bays, labs, or production floors.

Structured training design

A structured training design clarifies goals, practice time, and evidence of competence. Many programs sequence learning from safety and measurement to materials, fastening, power transmission, and then to hydraulics or pneumatics. Each module defines outcomes—such as assembling a gearbox to tolerance—and assessment criteria tied to checklists. Skill logs, job cards, and photos document progress. Short theory segments precede supervised practice, followed by reflection: what worked, what needs adjustment, and how to prevent errors next time. Capstone projects integrate multiple skills, like building a small power unit with aligned pulleys and guarded belts. This approach matches workshop-oriented learning with transparent milestones, helping trainers and learners track progress objectively and adjust pacing when needed.

Guided technical learning

Guided technical learning pairs learners with instructors who demonstrate techniques, model best practices, and provide immediate feedback. Demonstrations cover safe tool setup, instrument calibration, and correct body positioning to reduce strain. Checklists and standard operating procedures (SOPs) support consistency, while risk assessments teach how to identify pinch points, hot surfaces, or residual energy. Mentoring accelerates learning by highlighting subtle cues—bearing noise, belt flutter, or heat buildup—that indicate problems. Digital aids, such as short video micro-lessons and simple simulations, reinforce concepts between workshop sessions. Cross-disciplinary exposure to electrical basics (for motors, sensors, and drives) prepares learners to interact safely with mechatronic systems while staying focused on mechanical integrity.

Practical handling steps

Practical handling steps anchor repeatable results. A common sequence is: define the task and constraints; review drawings and torque specifications; plan tools, fixtures, and personal protective equipment; isolate energy sources (mechanical, electrical, pneumatic); clean and inspect surfaces; measure and mark; assemble with attention to fits and torque sequences; align and tension; verify movement and clearances; run tests; document results. Emphasize alignment methods (straightedge, laser, or dial indicators), thread care (chasing, anti-seize, thread lockers), and contamination control to protect bearings and seals. Recording measurements and outcomes builds a traceable history, enabling root-cause analysis and continuous improvement for future work.

Mechanical system basics, routine workshop exercises, structured training design, guided technical learning, and practical handling steps in context

In Germany’s workshop settings, these elements reinforce one another. Mechanical system basics provide the vocabulary; routine workshop exercises embed safe habits; a structured training design organizes progression; guided technical learning ensures quality feedback; and practical handling steps turn knowledge into reliable outcomes. Learners benefit from consistent supervision, standardized documentation, and realistic tasks that mirror the demands of local services in their area. As proficiency grows, trainees move from simple subassemblies to more complex systems, always supported by measurement discipline and clear criteria for acceptable work.

Conclusion Mechanic training anchored in workshops develops dependable skills through measured practice, standard procedures, and targeted feedback. By connecting theory to hands-on tasks, learners gain the confidence to diagnose issues, assemble with precision, and maintain equipment safely. The combination of structured modules, guided learning, and disciplined handling steps supports steady progress and consistent results across varied mechanical environments.