Food Packing Industry in Germany: Informational Overview

If you are from Germany and speak English, you may be interested in learning more about the organisation of food-packing processes. These typically include structured steps such as sorting, packaging, sealing and quality checks under hygiene rules. Such routines help ensure consistent preparation and handling within the German food-packing field.

Understanding Food Packing in Germany

The food packing sector in Germany represents a significant component of the country’s manufacturing landscape. This industry involves the preparation, packaging, and quality assurance of food products before they reach retail outlets and consumers. The sector employs thousands of workers across various facilities, ranging from small regional operations to large-scale industrial plants. Workers in this field handle diverse products including fresh produce, processed foods, frozen items, and bakery goods. The industry operates under comprehensive regulatory frameworks that govern every aspect of food handling and packaging operations.

Quality Checks Throughout the Process

Quality checks form the backbone of food packing operations in Germany. These procedures occur at multiple stages throughout the packaging process to ensure product safety and compliance with legal standards. Visual inspections identify physical defects, contamination, or packaging errors before products leave the facility. Many facilities employ both automated detection systems and manual inspection stations where trained personnel examine products for quality issues. Weight verification systems ensure accurate product quantities, while metal detectors and X-ray machines screen for foreign objects. Temperature monitoring maintains proper storage conditions for perishable items. Documentation of all quality check results creates traceability throughout the supply chain, allowing facilities to track products from reception through final packaging.

Hygiene Rules and Safety Standards

Hygiene rules in German food packing facilities follow strict national and European Union regulations. The Hazard Analysis and Critical Control Points (HACCP) system guides operational procedures, identifying potential contamination risks and establishing control measures. Workers must follow detailed hygiene protocols including hand washing procedures, proper use of protective clothing, and adherence to clean room practices in sensitive areas. Facilities maintain separation between raw and processed food zones to prevent cross-contamination. Regular cleaning schedules ensure equipment and work surfaces meet sanitary standards. Temperature controls preserve product integrity during storage and processing. All personnel receive mandatory hygiene training before beginning work, with periodic refresher courses to maintain awareness of proper practices. Health screenings and documentation verify that workers meet fitness requirements for food handling positions.

Packaging Structure and Materials

Packaging structure in the German food industry balances product protection, shelf life extension, and environmental considerations. Primary packaging makes direct contact with food products, using materials approved for food contact such as plastics, glass, aluminum, or paper-based materials. Secondary packaging groups individual items together, often incorporating cardboard boxes or shrink wrap for transport efficiency. Tertiary packaging prepares products for distribution, typically involving palletization and stretch wrapping for stability during shipping. Modified atmosphere packaging extends shelf life for fresh products by adjusting gas composition within sealed packages. Vacuum packaging removes air to preserve product quality and prevent spoilage. Sustainable packaging solutions increasingly incorporate recyclable materials and reduced plastic content, reflecting environmental priorities. Labeling requirements mandate clear ingredient lists, allergen warnings, nutritional information, and traceability codes on all packages.

Sector Overview and Industry Landscape

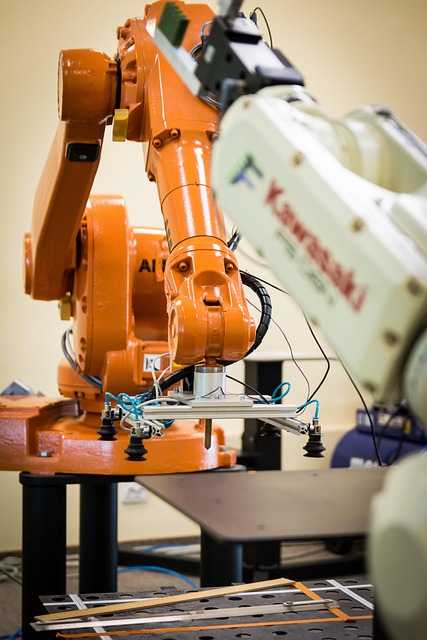

The sector overview of Germany’s food packing industry reveals a diverse and technologically advanced field. The industry serves both domestic consumption and export markets, with Germany’s central European location facilitating distribution across the continent. Automation has transformed many packaging operations, with robotic systems handling repetitive tasks while human workers focus on quality control, machine operation, and problem-solving roles. Seasonal fluctuations affect employment levels, particularly in facilities processing fresh produce or holiday-specific products. The industry encompasses various specializations including meat packing, dairy processing, bakery packaging, and prepared meal assembly. Regulatory compliance remains paramount, with facilities subject to regular inspections by food safety authorities. Industry associations provide guidance on best practices and represent sector interests in policy discussions. Technological innovation continues reshaping operations, with developments in smart packaging, track-and-trace systems, and sustainable materials influencing future industry direction.

Working Conditions and Requirements

Working conditions in food packing facilities vary depending on the specific products handled and facility size. Many positions involve standing for extended periods, repetitive motions, and work in temperature-controlled environments that may be cold for frozen food handling or climate-controlled for fresh products. Shift work is common, with facilities often operating multiple shifts to maximize production capacity. Physical demands include lifting, bending, and manual dexterity for packaging tasks. Safety equipment such as cut-resistant gloves, hairnets, and protective footwear is standard. Language requirements vary by facility, though basic German communication skills facilitate workplace integration and safety compliance. Some positions require minimal prior experience, with on-the-job training provided for specific tasks and equipment operation. Other roles demand specialized knowledge in quality assurance, machine maintenance, or logistics coordination.

Training and Skill Development

Training programs in the food packing industry equip workers with necessary competencies for safe and efficient operations. Initial orientation covers facility layout, emergency procedures, and basic hygiene requirements. Task-specific training teaches proper operation of packaging equipment, quality inspection techniques, and documentation procedures. Forklift certification enables workers to handle material transport responsibilities within warehouses. Quality assurance training develops skills in identifying defects, conducting measurements, and recording inspection results. Ongoing professional development opportunities allow workers to advance into supervisory or specialized technical roles. Some facilities partner with vocational schools to offer structured apprenticeship programs combining classroom instruction with practical experience. Cross-training initiatives prepare workers to perform multiple roles, increasing operational flexibility and career development prospects.

Future Trends and Industry Development

The German food packing industry continues evolving in response to technological advances, consumer preferences, and regulatory changes. Automation expansion will likely increase productivity while shifting workforce requirements toward technical and supervisory skills. Sustainability initiatives drive innovation in packaging materials, waste reduction, and energy efficiency. Consumer demand for transparency encourages enhanced traceability systems and detailed product information. Digitalization introduces data analytics for quality monitoring, predictive maintenance, and supply chain optimization. Labor market dynamics, including demographic changes and skill availability, influence recruitment strategies and workplace practices. Industry adaptation to these trends will shape the sector’s future structure and employment landscape, maintaining Germany’s position as a significant European food processing and packaging center.