Food Packing Industry in Chicago – Workflow Organization and Sector Overview

In Chicago, the food packing industry can be viewed as a process-driven environment built around repeatable workflows and clearly defined operational stages. This article outlines how food packing activities are generally structured, how coordination supports consistency, and how working conditions are shaped by production standards. The overview offers neutral, informational insight into the organization and characteristics of the food packing sector in Chicago, focusing on industry structure rather than specific opportunities.

The food packing industry in Chicago operates as a vital component of the regional economy, with facilities ranging from large-scale meat processing plants to specialized packaging operations for consumer goods. These operations require sophisticated systems to manage production flow, quality control, and workforce coordination across multiple shifts and departments.

Food Packing Industry in Chicago Structure and Scale

Chicago’s strategic location and transportation infrastructure have made it a natural hub for food processing and packaging operations. The industry encompasses various segments including meat processing, dairy packaging, frozen food preparation, and specialty food manufacturing. Major facilities typically operate 24-hour production schedules to meet demand from regional and national distribution networks.

The sector includes both large multinational corporations and smaller regional processors, each contributing to the city’s manufacturing base. These facilities often integrate multiple production lines, requiring careful coordination between receiving, processing, packaging, and shipping departments.

Workflow Organization in Production Facilities

Effective workflow organization forms the backbone of successful food packing operations. Production managers typically implement systematic approaches that begin with raw material receiving and inspection, followed by processing stages that vary depending on the specific product type.

The organization typically follows a linear progression from preparation areas through processing zones to final packaging and quality control checkpoints. Each stage requires specific timing coordination to prevent bottlenecks and maintain product freshness standards. Temperature control zones, sanitation protocols, and equipment maintenance schedules all factor into the overall workflow design.

Process-Driven Production Methods

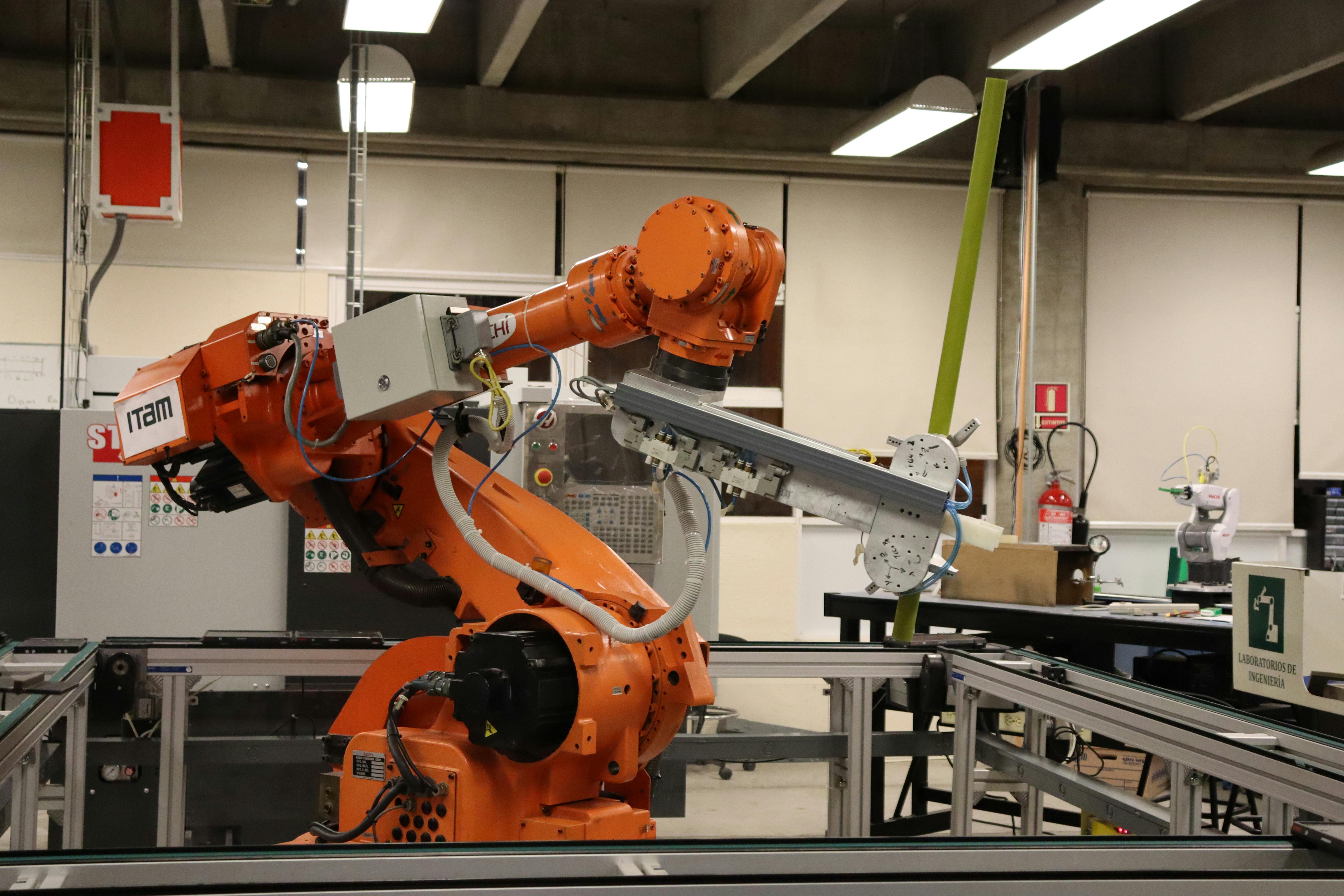

Process-driven production in food packing facilities relies on standardized procedures that ensure consistency and safety compliance. These processes typically incorporate automated systems for weighing, filling, sealing, and labeling products while maintaining human oversight for quality control and equipment monitoring.

Production lines are designed with specific capacity targets and timing requirements that must align with packaging material availability and shipping schedules. The integration of technology systems helps track production metrics, inventory levels, and quality indicators throughout the manufacturing process.

Operational Coordination Across Departments

Successful food packing operations require seamless coordination between multiple departments including production, quality assurance, maintenance, shipping, and administrative functions. Communication systems typically include shift handover procedures, production reporting protocols, and issue escalation processes.

Coordination extends to supplier relationships for raw materials and packaging supplies, as well as customer requirements for delivery schedules and product specifications. Many facilities utilize integrated software systems to manage these complex coordination requirements across all operational areas.

Sector Insight and Industry Trends

The Chicago food packing sector continues evolving with technological advances, changing consumer preferences, and regulatory requirements. Automation integration has increased in recent years, affecting both production efficiency and workforce requirements. Sustainability initiatives have also influenced packaging material choices and waste reduction programs.

Market demands for faster turnaround times and smaller batch sizes have pushed facilities to develop more flexible production systems. This trend has created opportunities for facilities that can adapt quickly to changing product specifications while maintaining quality standards and cost effectiveness.

Regulatory compliance remains a critical factor, with facilities required to maintain detailed documentation of production processes, ingredient sourcing, and quality control measures. These requirements influence both workflow design and staffing patterns across the industry.

Career Pathways and Skill Development

The food packing industry offers various career progression opportunities from entry-level production positions to specialized technical roles and management positions. Workers often develop skills in equipment operation, quality control procedures, and safety protocols that can transfer across different facilities and industry segments.

Training programs typically focus on food safety certification, equipment operation, and production efficiency techniques. Many facilities provide internal advancement opportunities for workers who demonstrate reliability and willingness to learn additional skills.

The sector values workers who can adapt to changing production requirements while maintaining attention to detail and safety compliance. Communication skills become increasingly important for positions involving coordination between departments or shifts.

Chicago’s food packing industry continues serving as an important employment sector while adapting to technological changes and evolving market demands. The combination of established infrastructure, skilled workforce, and strategic location positions the region’s facilities to remain competitive in the broader food manufacturing landscape.