Food Packing Industry in Bologna – Process Structure and Organisation

In Bologna, food packing activities are presented as process-driven routines focused on organised product handling. This article outlines how workflows are arranged, how steps are repeated in a structured way, and how controlled environments support stability and predictability across food packing operations.

The food packing industry in Bologna represents a significant component of the regional economy, combining traditional culinary heritage with modern industrial practices. This sector encompasses various operations, from small-scale artisanal packaging to large automated facilities. The organizational structure within these environments emphasizes precision, hygiene standards, and systematic approaches to handling perishable goods.

Process-Driven Packing in Bologna Facilities

Process-driven packing forms the backbone of food handling operations throughout Bologna. This approach involves breaking down packaging tasks into sequential steps, each designed to maintain product integrity while maximizing throughput. Facilities typically organize stations according to product type, with dedicated areas for weighing, sealing, labeling, and quality inspection. Temperature-controlled zones ensure that sensitive items like fresh cheese or prepared meats remain within safe ranges throughout the packing cycle. Equipment calibration occurs regularly to maintain consistency, and digital tracking systems monitor batch numbers and expiration dates. The emphasis on standardized procedures reduces variability and helps facilities meet both Italian and European Union food safety regulations.

Structured Workflows Within Packing Operations

Structured workflows define how materials move through packing facilities from receiving to dispatch. Raw products arrive at designated intake points where initial quality checks occur. Items then progress through cleaning stations if necessary, followed by portioning areas where products are divided according to specification. Packaging materials are stored separately and introduced at appropriate stages to prevent contamination. Each workflow stage includes checkpoints where supervisors verify compliance with hygiene protocols and packaging standards. Documentation accompanies products throughout their journey, creating traceability that allows facilities to identify and address issues quickly. This systematic organization minimizes bottlenecks and ensures that production targets align with order schedules.

Controlled Environments and Hygiene Standards

Controlled environments are essential to food packing operations in Bologna, where maintaining specific atmospheric conditions protects product quality. Facilities regulate temperature, humidity, and air circulation to prevent spoilage and bacterial growth. Access to packing areas is restricted, with personnel required to follow strict hygiene protocols including protective clothing, hand washing, and equipment sanitization. Surfaces and tools undergo regular cleaning using approved disinfectants, and waste removal follows designated procedures to avoid cross-contamination. Many facilities implement Hazard Analysis and Critical Control Points (HACCP) systems, identifying potential risks at each production stage and establishing preventive measures. Air filtration systems remove particulates, while positive pressure zones prevent external contaminants from entering sensitive areas. These environmental controls are subject to regular inspection by health authorities to ensure ongoing compliance.

Repeatable Routines and Operational Consistency

Repeatable routines establish the foundation for consistent output in food packing environments. Workers follow documented procedures for each task, from machine setup to final product inspection. Shift handovers include detailed briefings to ensure continuity, and supervisors conduct regular audits to verify adherence to established methods. Training programs familiarize personnel with specific protocols, emphasizing the importance of precision and attention to detail. Equipment maintenance schedules prevent unexpected breakdowns that could disrupt production flow. By standardizing operations, facilities achieve predictable results that meet customer expectations and regulatory requirements. This consistency also facilitates troubleshooting, as deviations from normal patterns become easier to identify and correct.

Operational Overview of Bologna’s Packing Sector

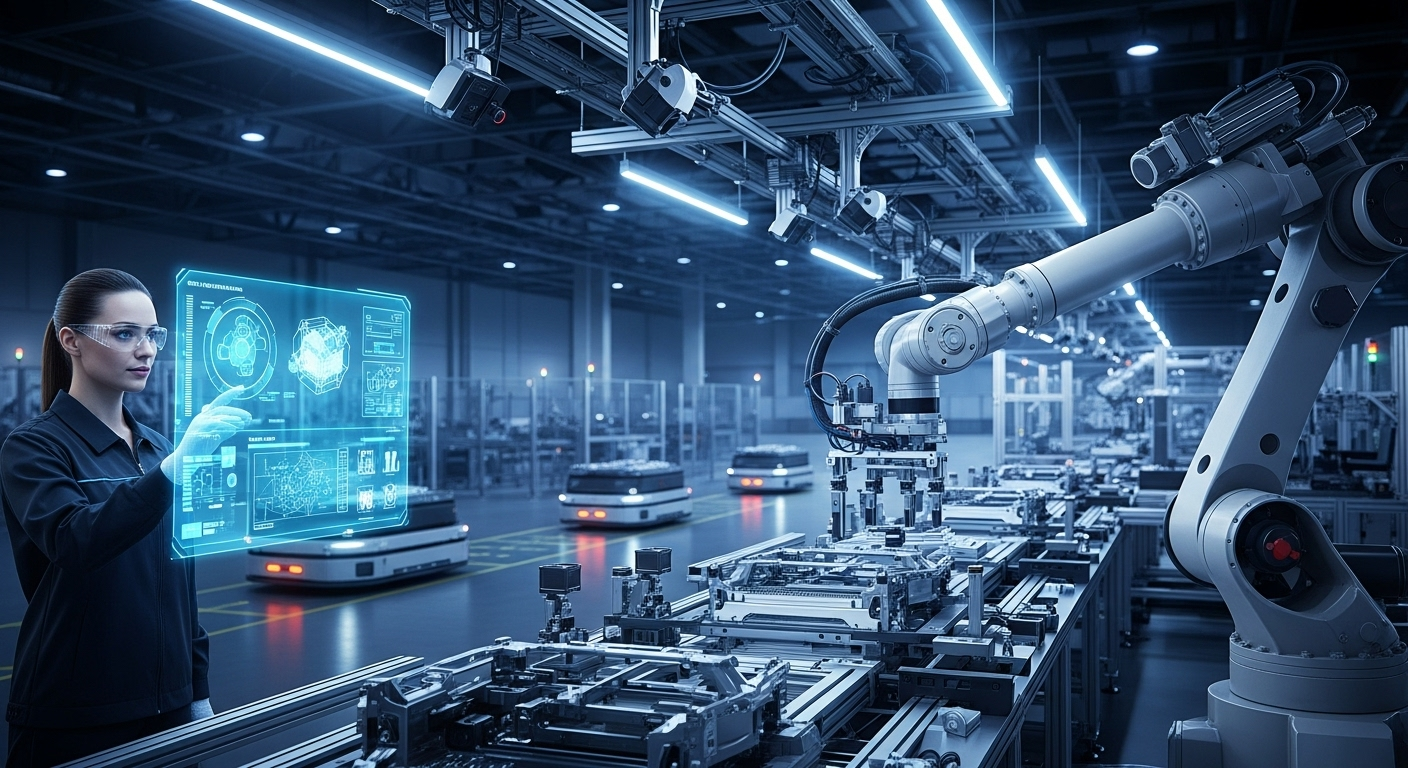

Bologna’s food packing sector encompasses diverse facility types serving local producers and larger distribution networks. Small operations may focus on specialty items like traditional balsamic vinegar or artisan pasta, employing manual packing techniques that preserve product character. Larger facilities handle higher volumes, utilizing automated systems for tasks such as weighing, wrapping, and case packing. The sector employs individuals across various roles, including machine operators, quality control technicians, logistics coordinators, and maintenance staff. Seasonal fluctuations affect staffing levels, particularly during peak production periods for specific products. Facilities often collaborate with agricultural suppliers and retail distributors, forming integrated supply chains that connect Bologna’s food heritage with modern commerce. Technological adoption continues to evolve, with some operations incorporating robotics and data analytics to enhance efficiency while maintaining the quality standards associated with Italian food products.

Workforce Considerations in Food Packing

The workforce in Bologna’s food packing facilities includes both permanent employees and temporary workers who support operations during busy periods. Roles vary in complexity, from entry-level positions focused on repetitive tasks to specialized positions requiring technical knowledge of machinery or quality systems. Training duration depends on the specific role and facility complexity, with basic positions typically requiring several days to weeks of instruction. Physical demands can be significant, as many roles involve standing for extended periods, repetitive motions, and handling of materials. Facilities generally provide appropriate safety equipment and implement ergonomic practices to reduce strain. While specific compensation details vary by employer and position type, the sector typically offers wages that reflect the skill level required and local labor market conditions. Advancement opportunities may exist for individuals who demonstrate reliability and willingness to expand their skill sets.

The food packing industry in Bologna continues to balance traditional values with contemporary operational demands. Through systematic organization, environmental controls, and commitment to quality, these facilities maintain the region’s reputation for excellence in food production while adapting to evolving market requirements and regulatory frameworks.