Food Packing Industry in Barcelona – Process Design and Operational Stability

In Barcelona, the food packing sector is often described as an organized production setting where clearly defined processes support stable output. This overview explains how packing systems are typically structured, how activities are coordinated, and how consistency is maintained across operations. The article offers general insight into working conditions and sector organization in Barcelona, without referencing specific opportunities.

Barcelona’s position as a logistics gateway, combined with its culinary culture and manufacturing base, gives the food packing sector a distinctive profile. Facilities span chilled ready-to-eat items, dry goods, beverages, and specialty products built for export. The operational challenge is to balance strict food safety standards with variable demand from retailers, HORECA, and e-commerce. Achieving that balance depends on clear process design, coordinated routines, and systems that keep throughput predictable while protecting quality.

Industry overview: Barcelona’s food ecosystem

The food packing industry in Barcelona is shaped by the Port of Barcelona, the Mercabarna wholesale hub, and a network of processors across Catalonia. Many plants are integrated into larger supply chains for fresh produce, seafood, dairy, and packaged foods. Regulatory frameworks such as HACCP, BRCGS, IFS Food, and ISO 22000 are common, with traceability and allergen control embedded in standard operating procedures. Seasonal peaks tied to tourism and fresh harvests mean production planning must align closely with inbound logistics and retailer forecasts to prevent bottlenecks and waste.

Organized production processes: where to start

Organized production processes begin with mapping product families and standardizing line setups. Clear work instructions, visual management, and short changeover routines (SMED principles) reduce downtime and variability. Layouts that separate high-risk from low-risk zones support hygiene flows, while kanban or milk-run replenishment keeps packaging materials available without overstocking. Digital checklists and line dashboards help teams monitor critical control points, overall equipment effectiveness (OEE), and giveaway on weight-controlled items. The result is tighter cycle times, fewer micro-stops, and consistent pack quality.

Operational stability in practice

Operational stability depends on predictable rhythms: reliable shift handovers, planned maintenance, and demand smoothing. Sales-and-operations planning (S&OP) creates a forward view of volume, enabling capacity buffers and labor planning without last-minute scramble. Preventive maintenance windows, coupled with spare-parts kits for common failures, lower mean time to repair. For chilled categories, contingency plans for refrigeration, sanitation, and hold-and-release protocols safeguard product integrity. Stability also requires supplier coordination—approved packaging specs, performance certificates, and inbound quality checks reduce line-speed disruptions.

Coordinated routines across functions

Coordinated routines align production, quality, maintenance, and logistics. Daily tiered meetings surface issues quickly, from material shortages to labeling errors. Standard handover templates ensure each shift understands machine states, pending quality holds, and changeovers. Cross-training supports flexible staffing, while andon signals and stop-the-line rules empower operators to address defects early. Warehouse teams synchronize with production via time-phased staging of pallets, labels, and films, minimizing travel and search time. Together, these routines sustain throughput and reduce rework.

Food packing industry in Barcelona: outlook

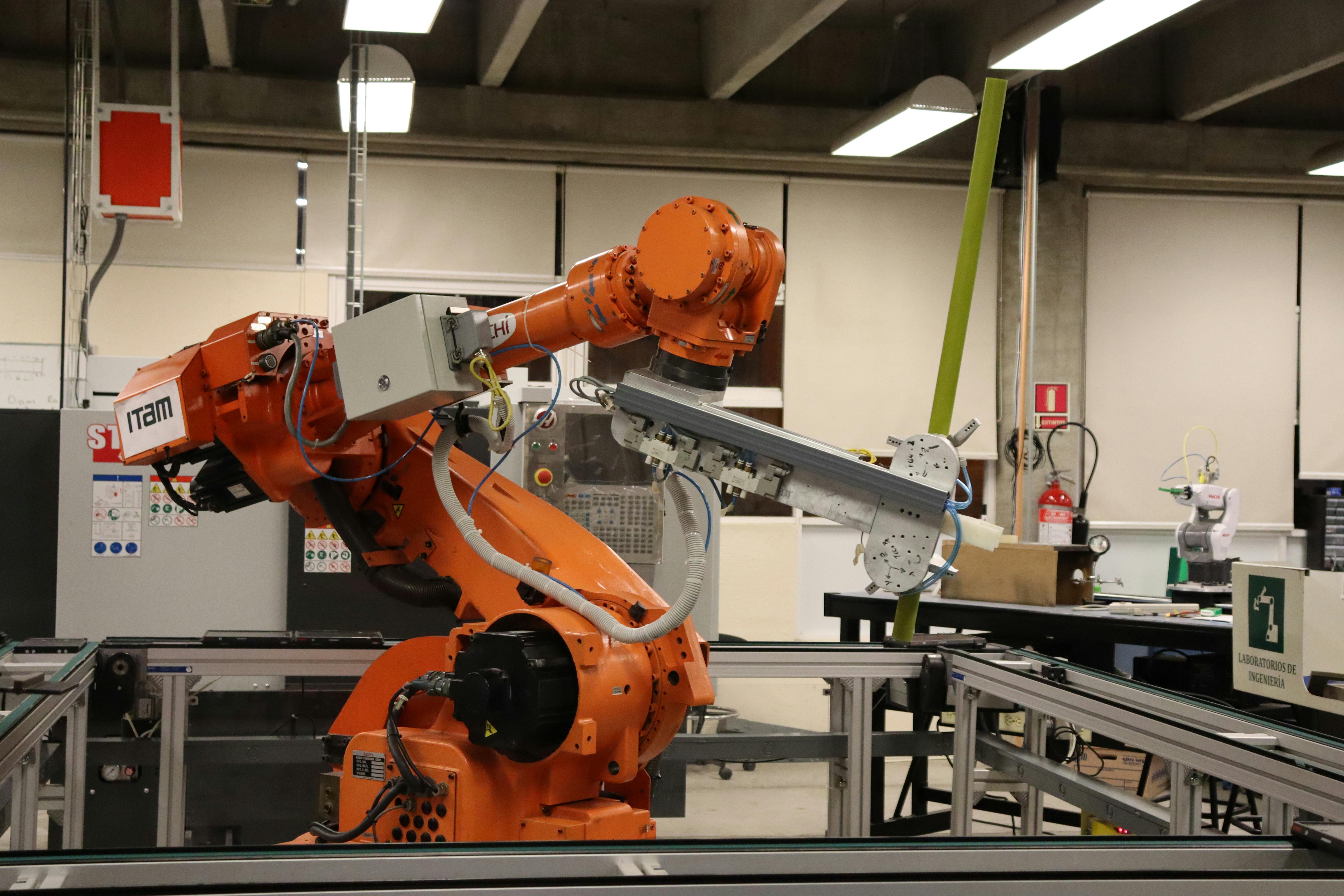

Looking ahead, facilities in the area are expanding traceability and real-time analytics to manage short runs and private-label variants. Automation—collaborative robots for case packing, vision systems for seal inspection, and in-line weight control—improves consistency without sacrificing agility. Sustainability targets are influencing material choices, with more mono-material films and recycled-content cartons entering specifications. Local services specializing in equipment integration, sanitation, and calibration support continuous improvement, helping plants adapt to demand shifts while maintaining safety and compliance.

Practical blueprint for process design

A practical blueprint includes five layers: product and packaging specification control; hygienic zoning and validated cleaning routines; right-sized inventory and material flow; standardized work with built-in quality checks; and a cadence of review through daily and weekly performance huddles. Document control ensures operators always use current instructions, while deviation management captures learnings. Pilot runs validate new SKUs before scale-up, and line trials for alternative materials de-risk change. These practices embed resilience into everyday operations.

Metrics that reinforce stability

Measure what matters and make it visible. Core metrics include OEE, first-pass yield, customer complaints per million units, sanitation non-conformities, on-time in-full (OTIF), and near-miss safety reports. For fresh and chilled lines, temperature compliance and dwell times are essential. A simple tiered KPI board—from line to site—keeps focus aligned. Weekly problem-solving using PDCA or DMAIC turns trends into targeted actions, while periodic audits verify that controls remain effective as product mixes evolve.

Workforce and skills in a regulated setting

People anchor process reliability. Competency matrices clarify who can operate which lines, perform changeovers, or conduct CCP checks. Microlearning modules and short refreshers sustain good practices, especially for hygiene, allergen control, and labeling accuracy. Ergonomic assessments and rotation plans reduce fatigue on repetitive tasks like case erecting or manual loading. Clear escalation paths and incident reviews foster a learning culture, helping teams maintain standards even during volume spikes or staffing constraints.

Integrating suppliers and logistics partners

Close coordination with ingredient, primary packaging, and secondary packaging suppliers reduces surprises on the line. Vendor scorecards highlight delivery precision and material performance, while dual-sourcing critical films or trays mitigates risk. Collaboration with carriers and cold-chain providers—time-slotting, temperature monitoring, and dock scheduling—keeps flows steady. In your area, leveraging consolidated inbound deliveries through regional hubs can cut dwell time and improve freshness, particularly for high-turn SKUs moving to retailers and foodservice clients.

Continuous improvement and future readiness

Sustained gains come from small, frequent improvements: reducing label change time, refining sealing parameters, or reorganizing point-of-use storage. Digital traceability, electronic batch records, and automated vision checks will continue to expand, supporting both compliance and speed. As sustainability regulations evolve, early trials with recyclable materials and lightweight designs can preserve line efficiency while lowering environmental impact. With disciplined process design and coordinated routines, Barcelona’s food packing sector can maintain operational stability as demand and product portfolios shift.

Conclusion In Barcelona’s dynamic market, operational discipline is the backbone of safe, efficient food packing. By aligning process design with rigorous quality systems, fostering coordinated routines, and planning proactively with partners, facilities can protect consistency and respond to change without compromising safety or service.