Food Packing in Frankfurt – Operational Steps and Industry Structure

If you speak English and live in Frankfurt, you can learn more about how food-packing processes are typically organized. The field uses stable routines, clear task division and methodical steps that support consistent handling of packaged goods.

Stable Routines in Food Packing Operations

Food packing facilities in Frankfurt maintain consistent daily operations through established protocols. Workers typically begin shifts with equipment checks and safety briefings. Standard procedures include sanitizing workstations, verifying packaging materials, and reviewing production schedules. These stable routines ensure product quality while maintaining operational efficiency throughout the facility.

Most facilities operate on rotating shifts to accommodate continuous production demands. Morning shifts often handle fresh product preparation, while afternoon teams focus on packaging completion and quality control verification.

Clear Task Division Within Packaging Teams

Effective food packing operations rely on specialized role assignments. Production lines typically include sorting specialists who categorize products by size, quality, or destination. Packaging operators handle the actual wrapping or container placement processes. Quality control inspectors monitor each stage to ensure compliance with food safety standards.

Support roles include machine operators who maintain packaging equipment, inventory coordinators who manage material supplies, and supervisors who oversee workflow coordination. This division ensures each team member develops expertise in specific areas while contributing to overall productivity.

Methodical Steps in the Packaging Process

Food packaging follows systematic sequences that vary by product type. Initial steps typically involve product inspection and sorting based on predetermined criteria. Items then move through cleaning or preparation stages before entering automated or manual packaging systems.

Labeling represents a critical step where products receive identification codes, expiration dates, and regulatory information. Final stages include quality verification, weight checking, and preparation for distribution. Each methodical step includes checkpoint protocols to maintain consistency and prevent errors.

Frankfurt Packing Structure and Facilities

Frankfurt hosts numerous food packaging facilities ranging from small specialty operations to large industrial complexes. The city’s strategic location provides access to regional food producers and efficient distribution networks throughout Germany and Europe.

Major facilities often feature multiple production lines capable of handling different product categories simultaneously. Modern installations incorporate automated systems for high-volume processing while maintaining manual stations for specialized or delicate items.

Controlled Workflow Stages and Quality Management

Workflow management systems coordinate product movement through various processing stages. Digital tracking systems monitor progress from initial receipt through final packaging completion. Temperature-controlled environments maintain product integrity for perishable items.

Quality checkpoints occur at regular intervals throughout the workflow. These include visual inspections, weight verification, seal integrity testing, and packaging material assessment. Documentation systems record each stage for traceability and regulatory compliance.

| Facility Type | Processing Capacity | Typical Products | Operational Features |

|---|---|---|---|

| Small Specialty | 500-2,000 units/day | Artisan foods, organic products | Manual packaging, custom labeling |

| Medium Industrial | 10,000-50,000 units/day | Processed foods, beverages | Semi-automated lines, quality labs |

| Large Commercial | 100,000+ units/day | Mass market products | Fully automated systems, 24/7 operations |

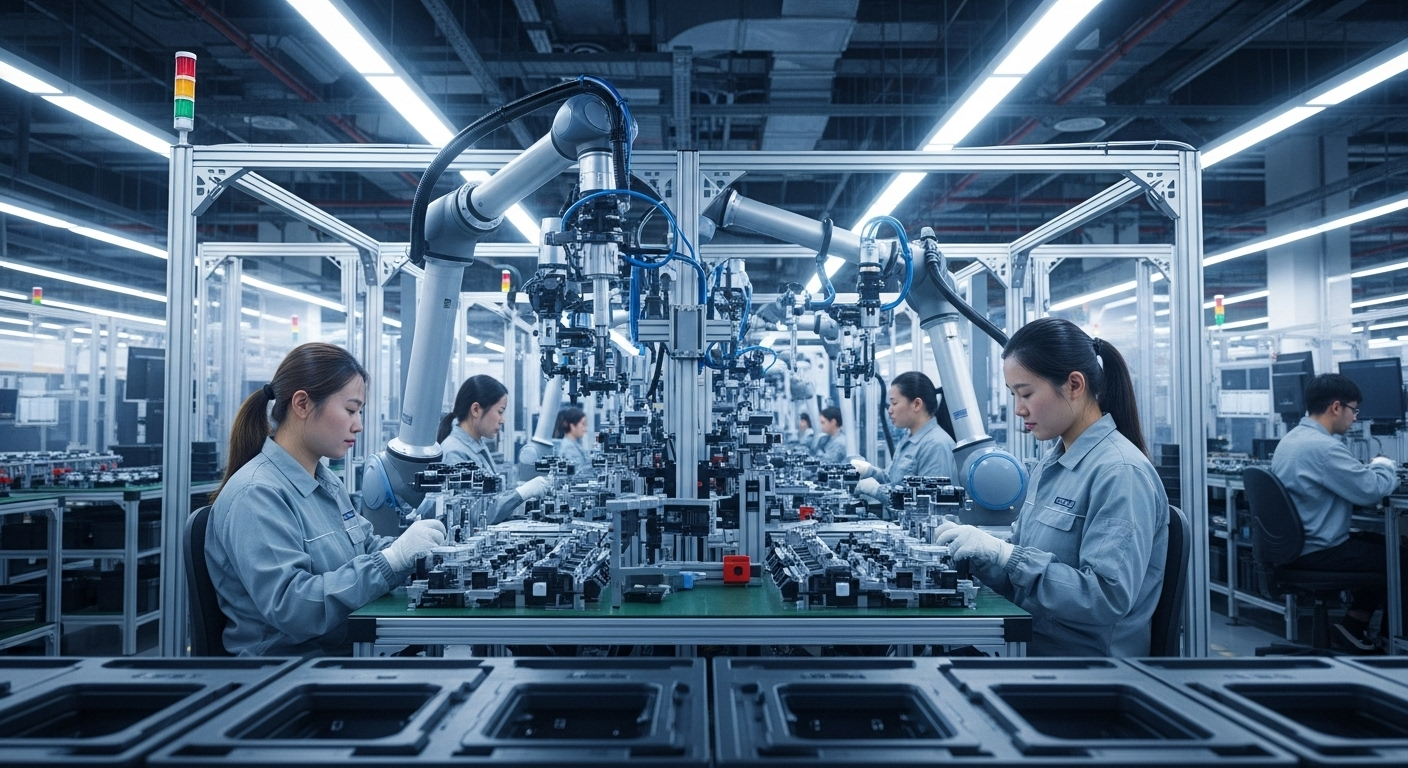

Technology Integration in Modern Packaging

Contemporary food packing facilities increasingly incorporate advanced technologies to enhance efficiency and accuracy. Automated sorting systems use sensors to categorize products based on multiple criteria simultaneously. Robotic packaging arms handle repetitive tasks while reducing human error rates.

Digital monitoring systems track production metrics in real-time, allowing supervisors to identify bottlenecks or quality issues immediately. Integration with inventory management systems ensures adequate material supplies while minimizing waste.

Frankfurt’s food packing industry demonstrates how systematic approaches and clear organizational structures create efficient operations. The combination of stable routines, methodical processes, and controlled workflows enables facilities to meet demanding production schedules while maintaining quality standards. Understanding these operational frameworks provides valuable insight into the complexity and precision required in modern food packaging operations.